A Critical Yet Overlooked Component in ESD Grounding Systems: Footwear Testing

In electrostatic discharge (ESD)-sensitive environments like electronics manufacturing and precision instrument assembly, a robust ESD grounding system is fundamental to product protection. While attention often focuses on wrist straps and grounded workstations, a key dynamic source of electrostatic charge is frequently overlooked: the moving human body and its final physical barrier to earth—ESD footwear or heel straps. Failure in foot grounding means accumulated electrostatic charges on the human body cannot dissipate safely, posing a constant risk of hidden yet catastrophic ESD events that may damage components or degrade product performance.

The hazard of footwear grounding failure is insidious. Unlike wrist strap failures that may trigger alarms, compromised foot grounding often escapes immediate detection. Operators may assume they are in a safe state while unknowingly carrying high-voltage static charges through sensitive areas. Every incidental movement or contact harbors ESD risks. Such “hidden failures” pose an amplified threat to modern high-density microelectronics, creating hard-to-trace batch quality defects.

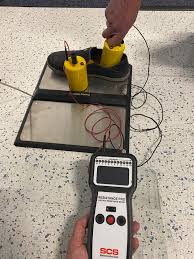

Thus, footwear testing must be a mandatory procedure in ESD control programs. Its core lies in using specialized footwear testers to regularly and systematically verify the effectiveness of personnel foot-grounding systems. These instruments comply with standards such as ANSI/ESD S20.20 and STM97.1/97.2, designed to precisely measure the total system resistance of the “person-shoe-floor” path to ground. The pass criterion typically requires resistance below 35 megohms (3.5 × 10⁷ Ω), ensuring electrostatic charges dissipate at a safe rate.

Proper use of footwear testers is critical:

- Personnel must wear their routine ESD footwear or heel straps.

- Stand fully on the tester’s metal electrode plates with both feet.

- Maintain steady hand contact with the tester’s handheld electrode.

- The instrument automatically applies test voltage, measures resistance, and displays “PASS” or “FAIL.”

Integrating footwear testing into daily ESD management—such as pre-shift or pre-EPA-entry checks—and maintaining comprehensive records are indispensable for building a reliable electrostatic protection system. Neglecting foot grounding leaves a critical gap in meticulously constructed ESD defenses. Only by monitoring personnel grounding (both hands and feet) as an integrated system, with footwear testers serving as routine guardians of ESD-sensitive zones, can hidden electrostatic threats be eliminated. This ensures product and environmental safety, establishing foot grounding as the indispensable first line of defense against ESD.